Eco Bearings design and manufacture seawater separation units for use in ships water lubricated tailshaft arrangements.

The design hold DNV approval in principle and enable condition based maintenance notations for all classes.

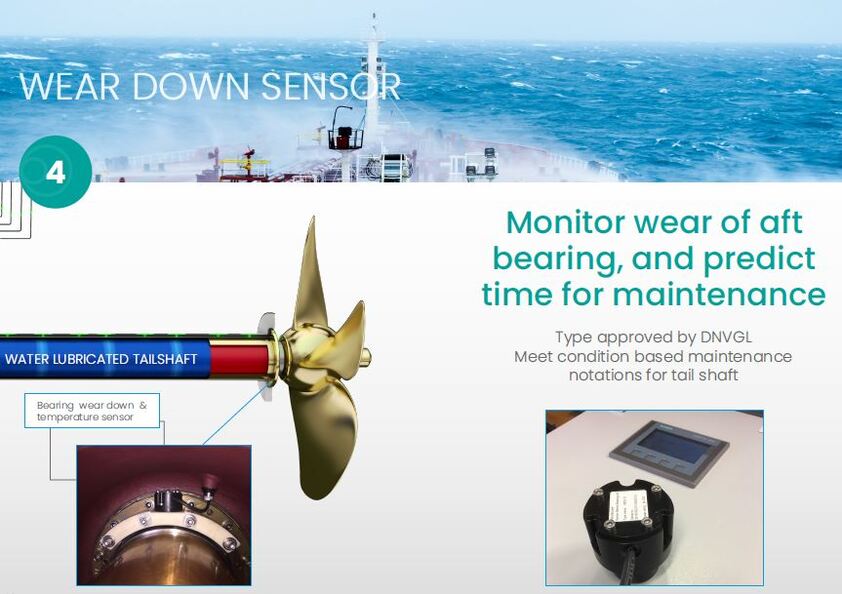

The type approved wear down sensor log and trend propeller bearing wear, and gives input to vessels maintenance planning.

The design hold DNV approval in principle and enable condition based maintenance notations for all classes.

The type approved wear down sensor log and trend propeller bearing wear, and gives input to vessels maintenance planning.